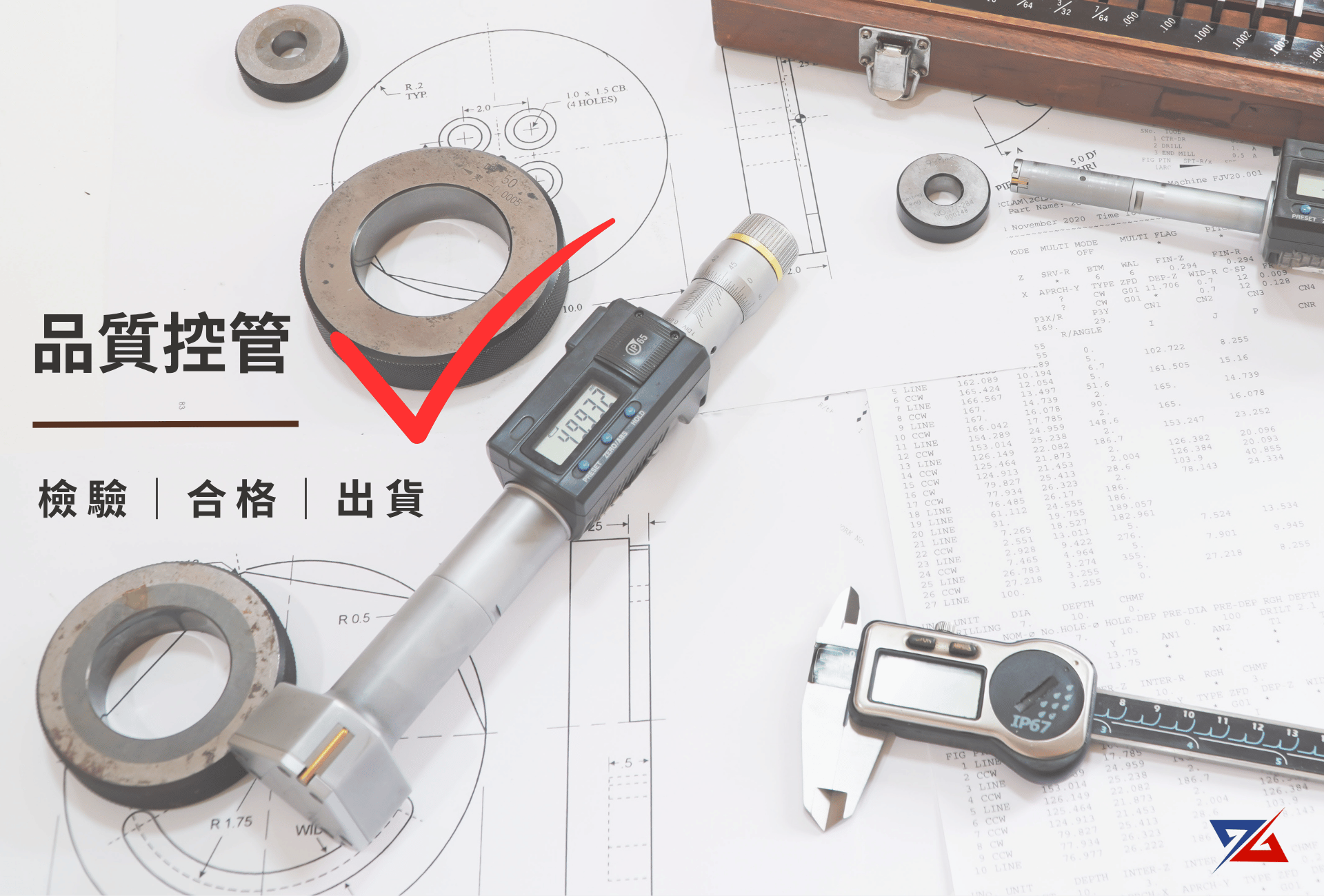

Inspection|Approval|Shipment

——The final step before shipment — and the most important one——

To ensure mold dimensional accuracy meets customer requirements, we use high-precision measuring equipment to conduct comprehensive inspections before shipment.

All key sizes are checked based on the drawing and recorded in a full inspection report to make sure they are within tolerance.

Our measurement equipment includes:

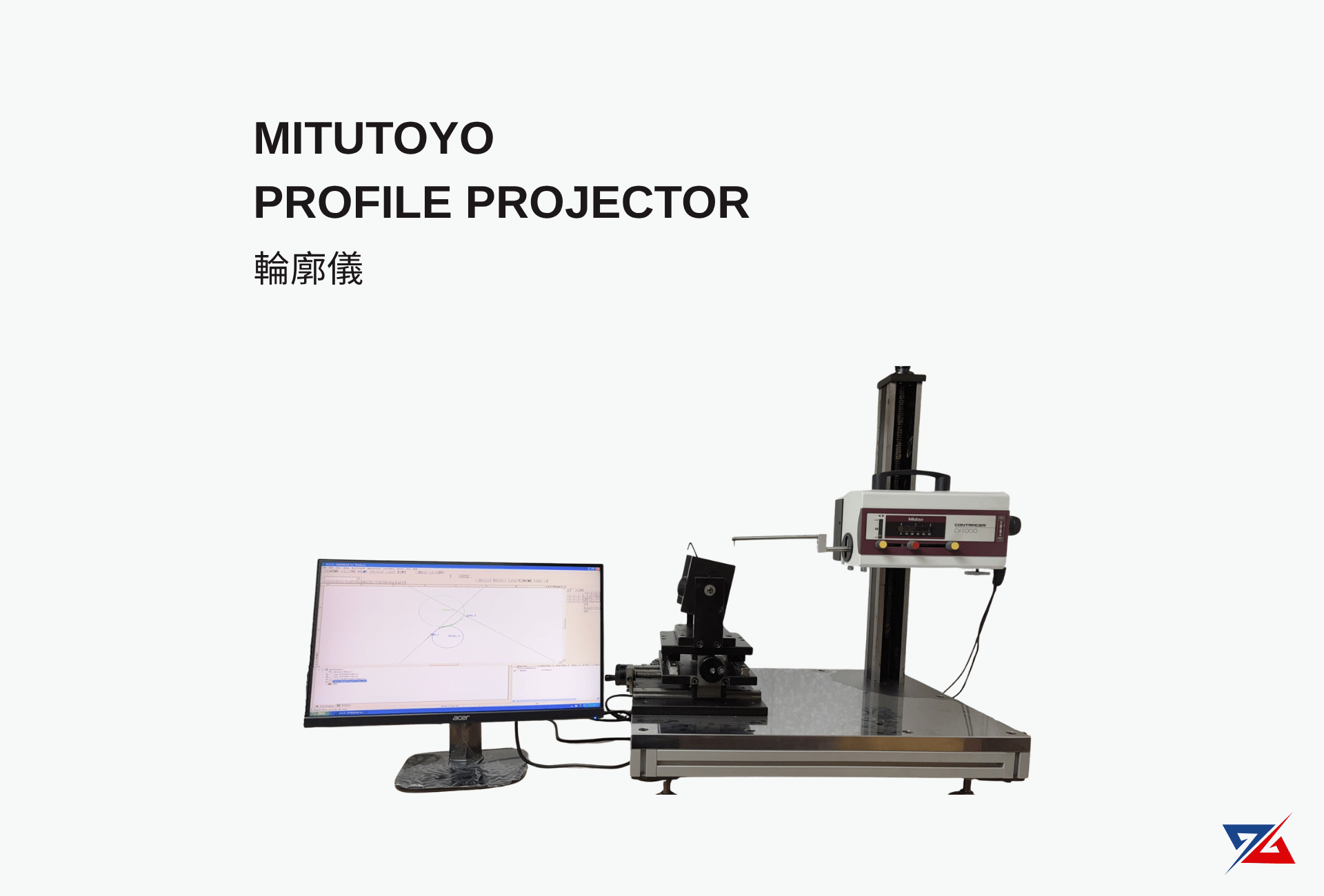

- Inspecting whether the mold’s profile matches the design drawings. Commonly used to check irregular shapes such as curved surfaces, inclined planes, arcs, and grooves.常應用於檢查曲面、斜面、弧形、凹槽等不規則形狀。

- Measuring flat dimensions such as length, width, diameter, angle, and hole pitch. Applicable for screws, hardware parts, and contour inspection.

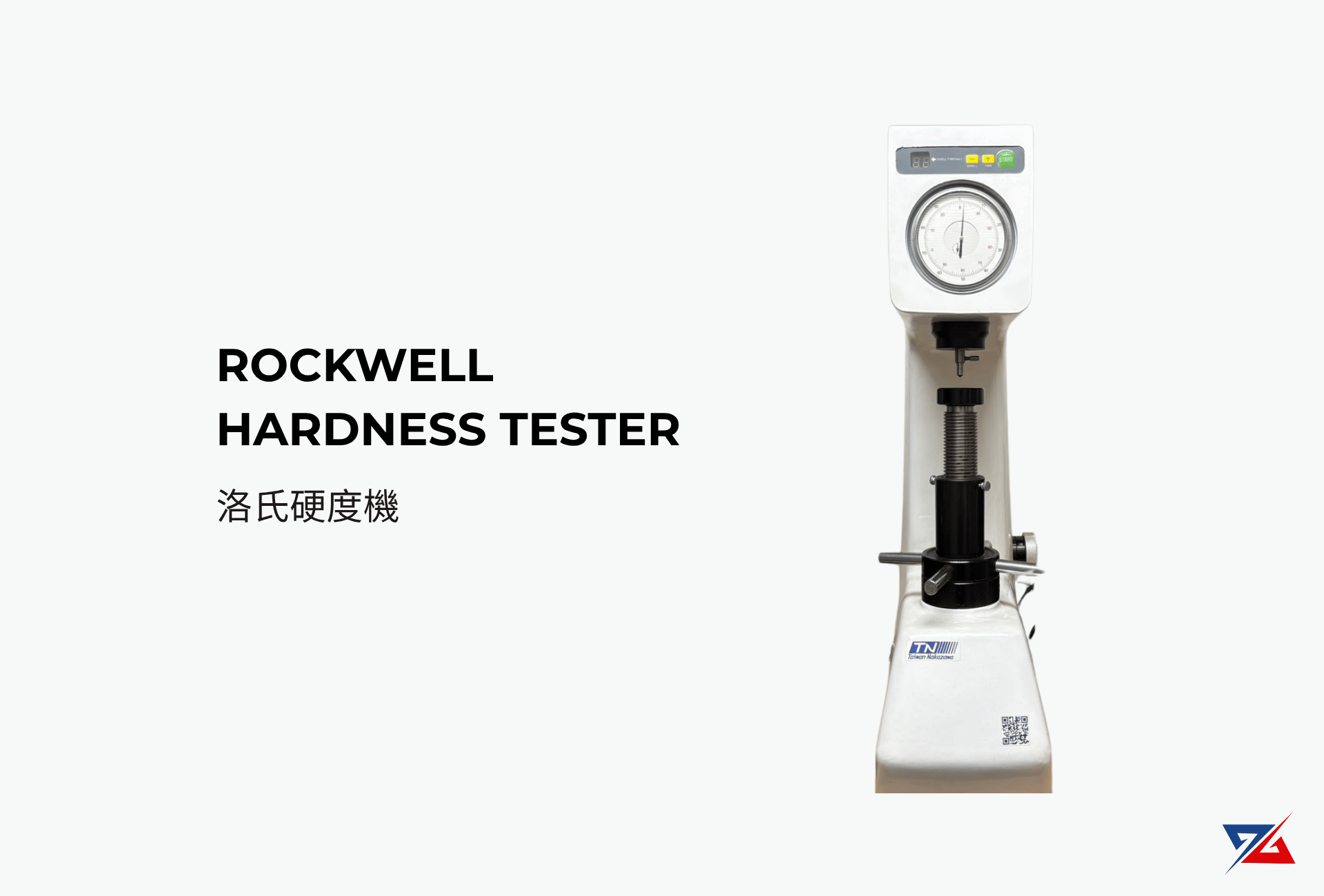

- The Rockwell hardness tester is used to measure the hardness of metals and other materials. It determines hardness by pressing an indenter into the material and measuring the depth of the indentation.

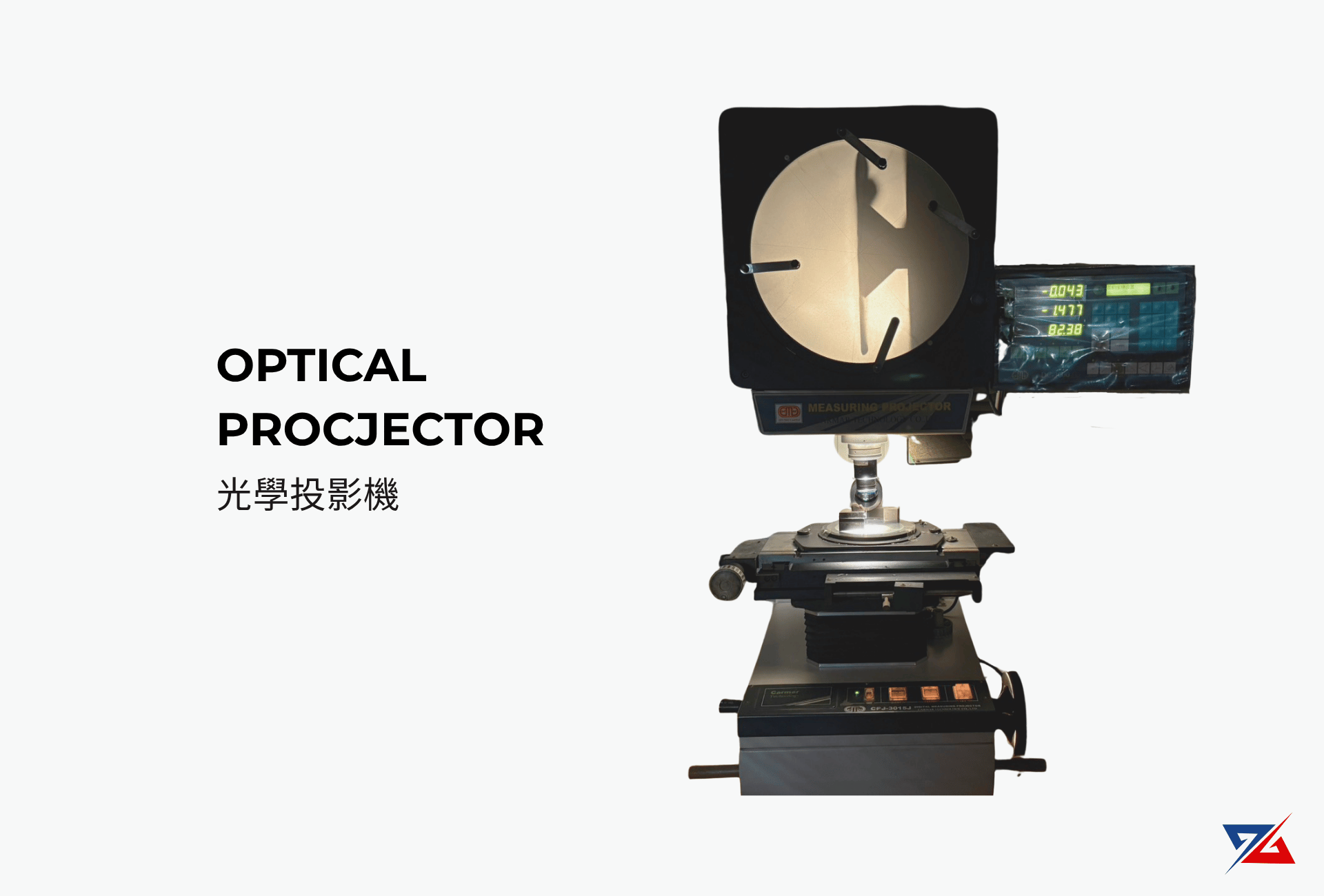

- An optical projector is a non-contact measurement tool commonly used to magnify the contours of molds or screws. It allows comparison with sample patterns to verify dimensional accuracy.

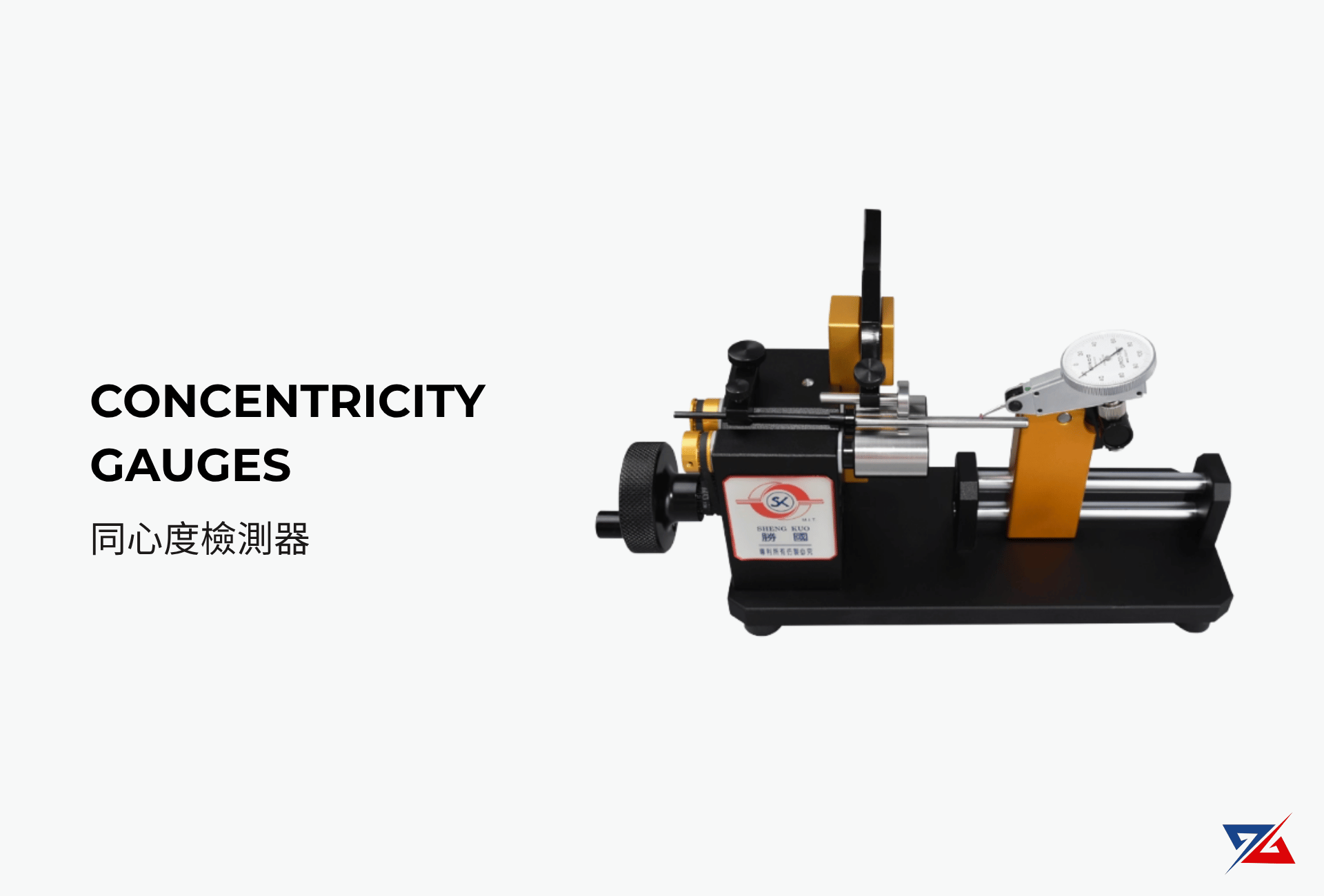

- A concentricity tester is used to check whether the outer diameter, inner diameter, or axis of a workpiece is aligned with the reference center. It is commonly applied to rotating parts such as inserts, sleeves, and screws to ensure dimensional concentricity.

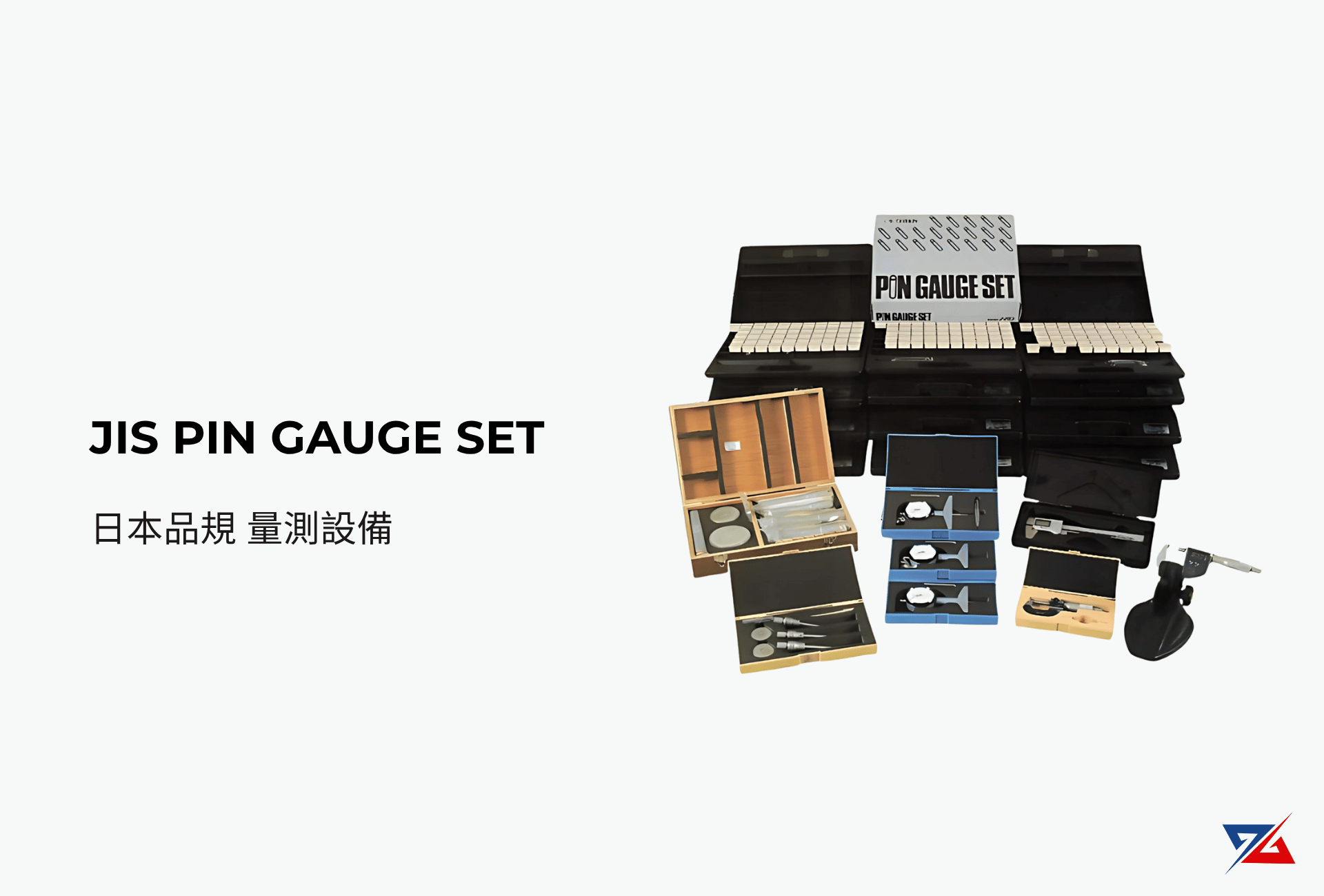

- A JIS Pin Gauge Set is a collection of precision pins made according to Japanese Industrial Standards (JIS). It is used for measuring and inspecting small holes with high accuracy.