TONG Z SUPER RIGID ALLOY MOLD CO.,LTD.

TONG Z SUPER RIGID ALLOY MOLD CO.,LTD.

Multi-station

— From Design to Forming, Tong Z Deconstructs It for You —

Whether for hollow rivet dies, automotive screw dies, or various fastener cold and hot forging dies, Tong Z provides customized designs tailored to your needs. Our multi-stage forming process uses phased deformation to effectively reduce the load on each mold, completing fastener extrusion within precise dimensions. Additionally, the innovative QSD mold helps solve issues such as burrs, oil entrapment, and sharp corners being rounded.

Through simulation analysis of forming pressure, we ensure dimensional and tolerance stability, maintaining mold concentricity within 0.01mm. We guarantee that fillets and chamfers meet customer requirements. Coupled with CNC machines and professional CAD/CAM software, we deliver high-precision, intricate fastener molds.

— Expert Multi-Station Die Design, Solving Forming Challenges —

We have extensive experience in multi-station die design and understand how each forming process impacts mold durability and quality.

From drawing evaluation to mass production adjustments, we quickly identify issues and provide effective solutions. Whether it’s unstable screw or fastener dimensions, punch or pin breakage, or appearance defects, we have successfully helped customers overcome these challenges.

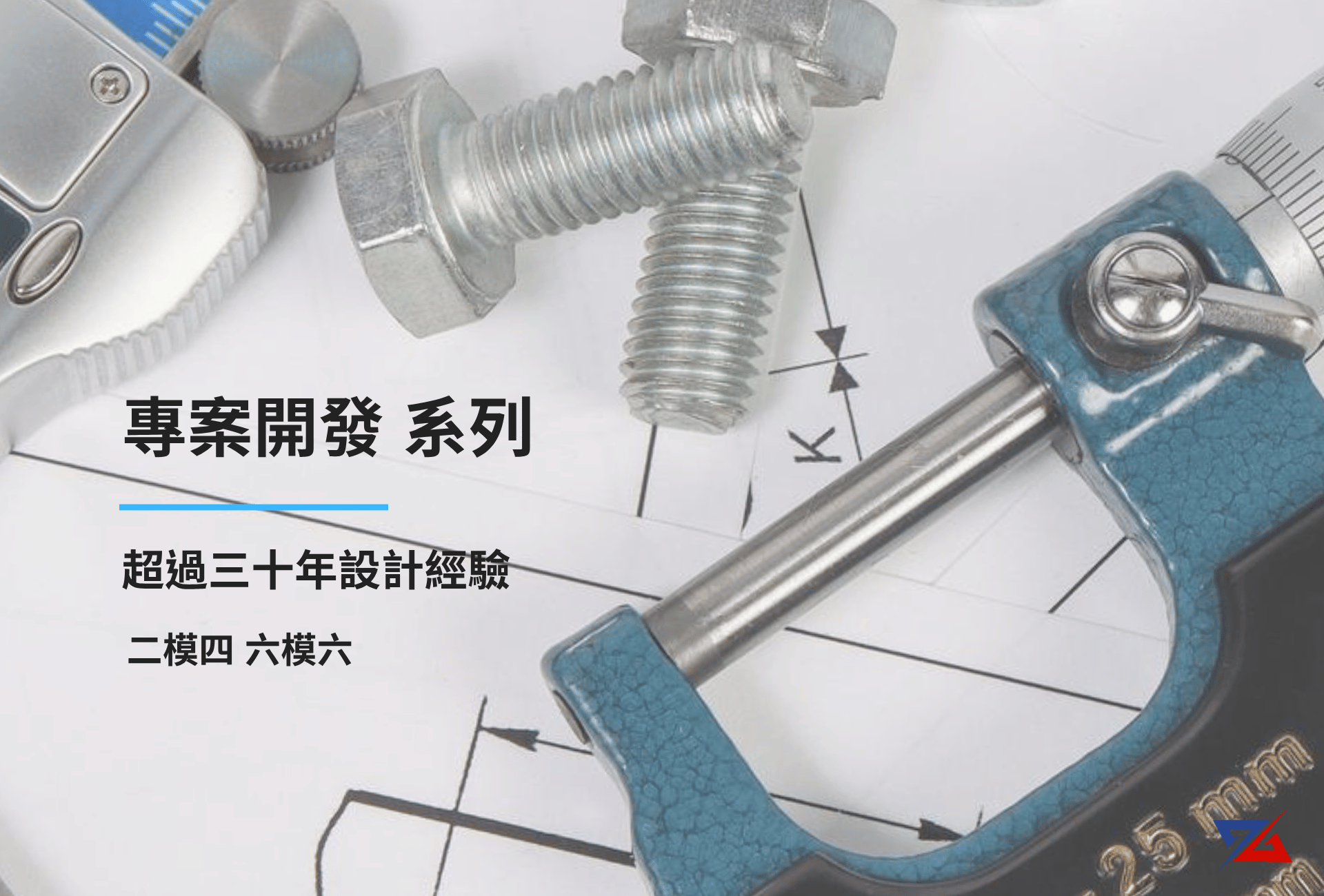

Kindly provide the following details, and we will be glad to serve you.

- 2D drawing CAD / DWG

- 3D drawing IGS / STEP

- Wire diameter: Ø____mm

- Material: Carbon Steel / Stainless Steel / Alloy Steel

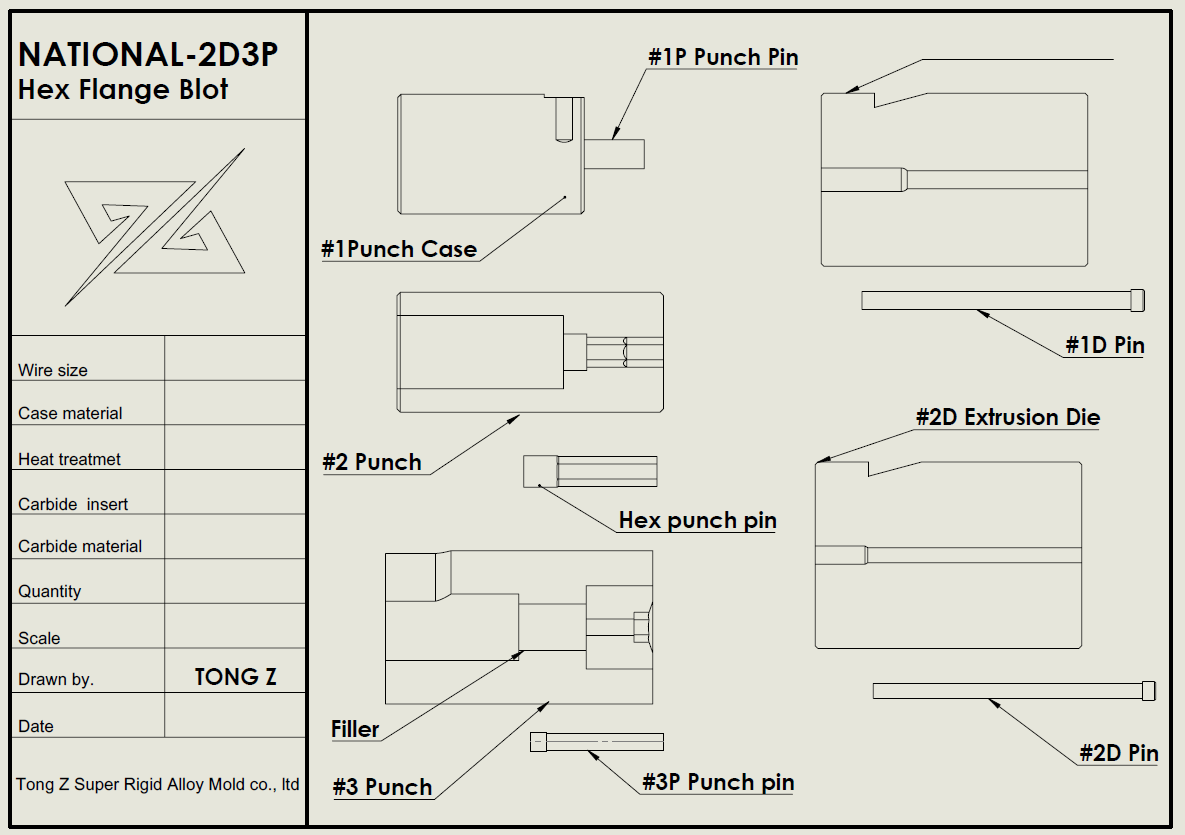

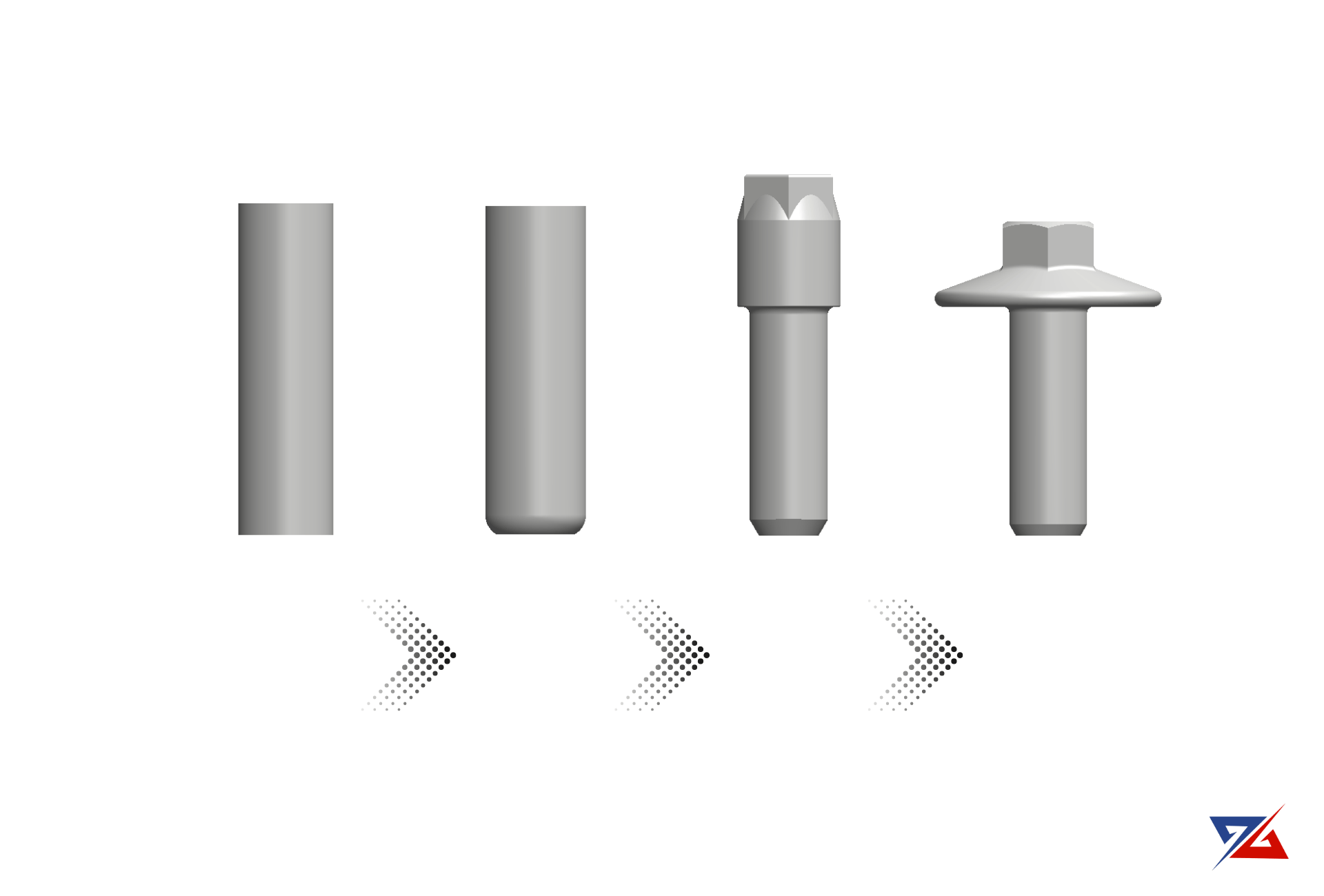

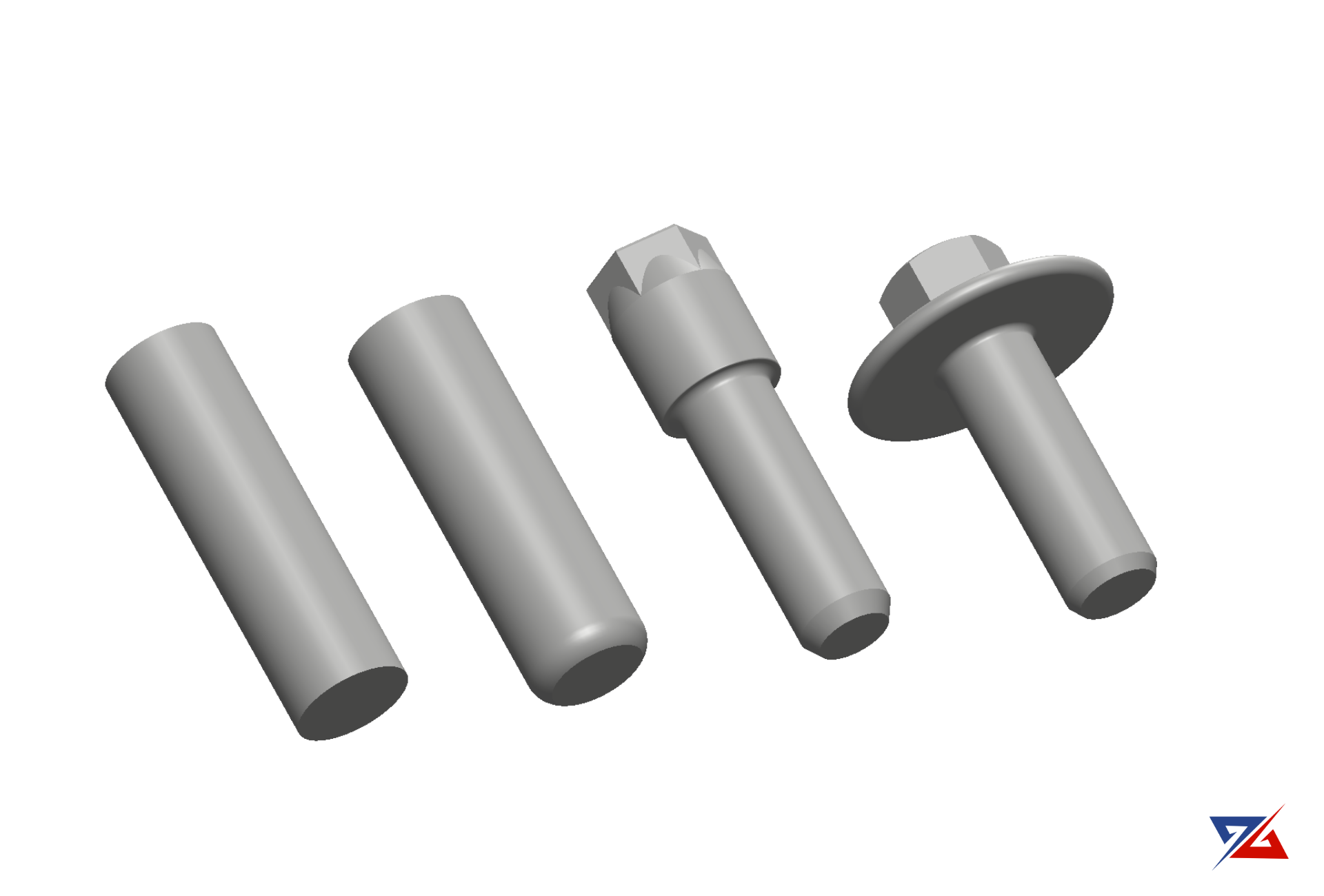

- 2-Die 3-blow blot Example (Hexagonal Washer)

- Screw Forming Preview

— Forming Simulation —

Based on the screw specifications and machine parameters provided by our customers, we use simulation software to accurately calculate the required die dimensions and predict material flow, deformation trajectories, and stress concentration areas.

Through mold flow simulation, potential defects such as cracking, fractures, air entrapment, and uneven flow can be identified and eliminated in advance.

— Mold Flow Analysis —

After detailed discussions with customers, we help choose the best design. This reduces mold wear and punch breakage, shortens setup and trial times, and boosts production efficiency and product quality.

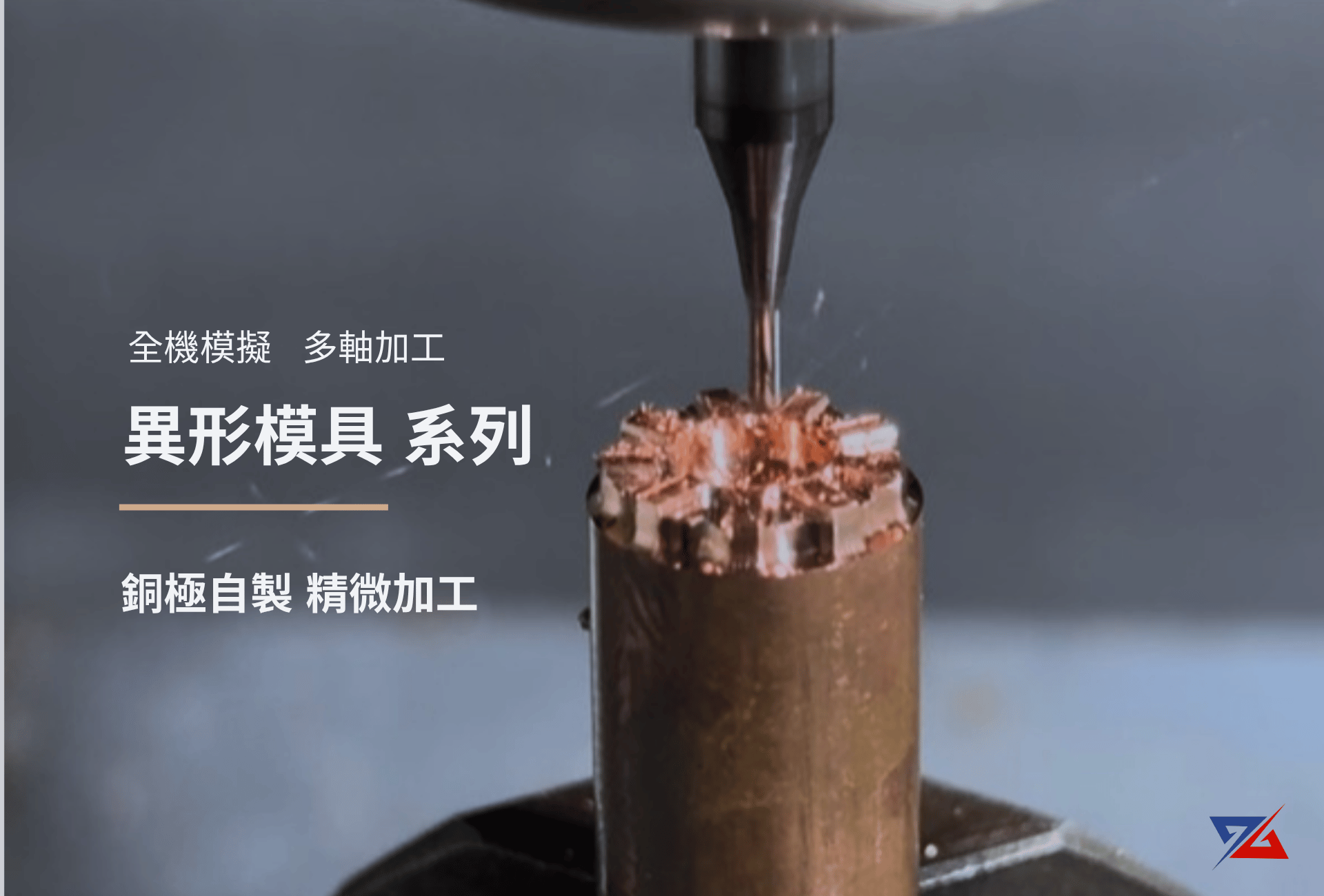

— No matter how complex the shape, every detail is precisely crafted —

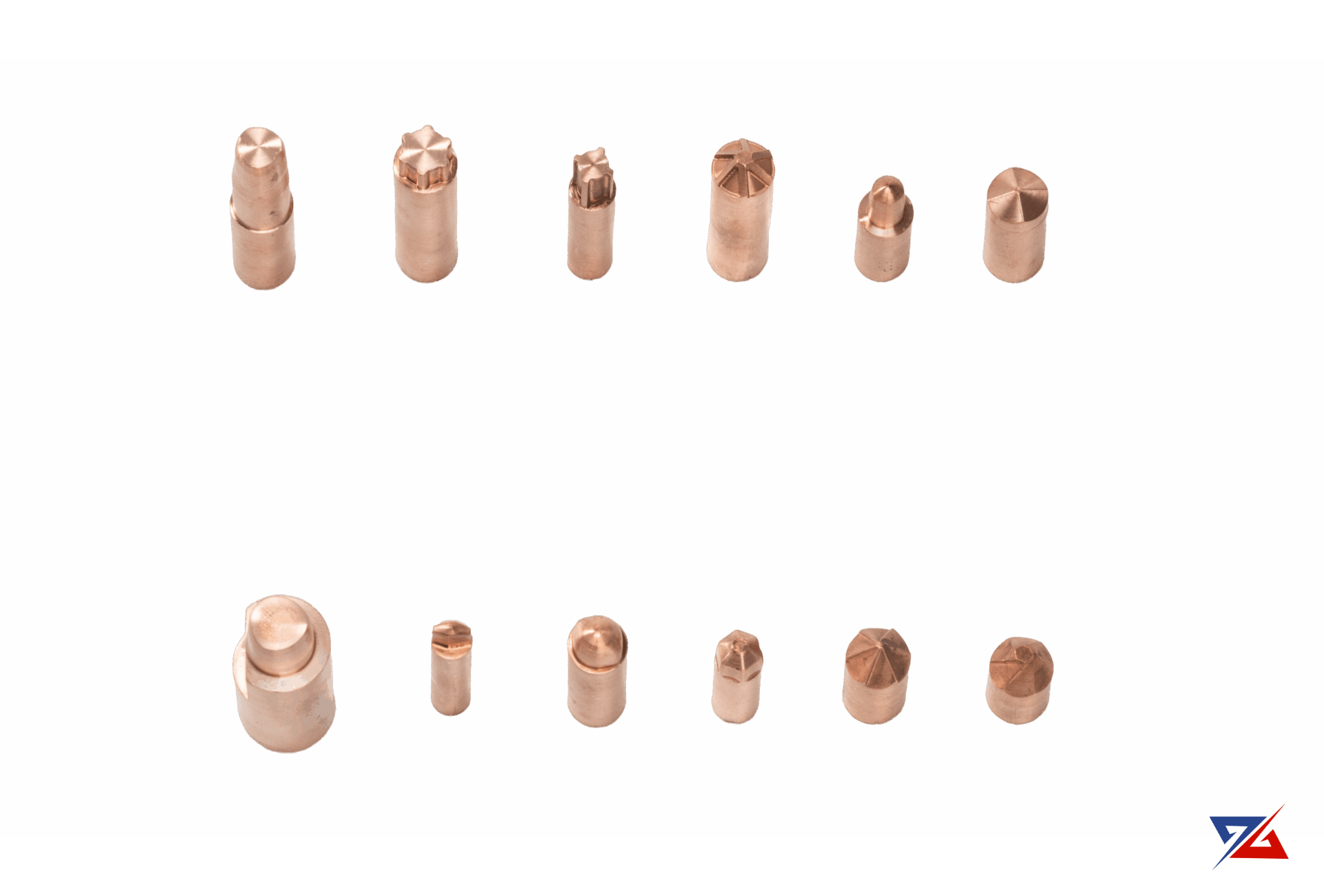

Tong Z specializes in designing and manufacturing various complex shapes, including star,TROX ,hexagonal, oval, eye-shaped, fisheye, and toothed patterns. Using CAD/CAM systems and multi-axis machining technology, we ensure molds achieve high precision and consistency, helping you create diverse screw products.

- EDM copper electrode

- Product Overview