About uS

Our value lies in solving our clients’ problems.

TONG Z integrates CNC machining and automated inspection to ensure precision, efficiency, and consistent quality. While honoring traditional craftsmanship, we advance smart manufacturing through continuous innovation.

We know that a high-quality mold goes beyond technique—it drives efficiency and boosts our clients’ competitiveness. At TONG Z, we gladly share our expertise in structure, materials, and process to help clients adapt and find the best-fit solutions.

東立超硬合金模具

Carbide Screw Mold Design and Manufacturing

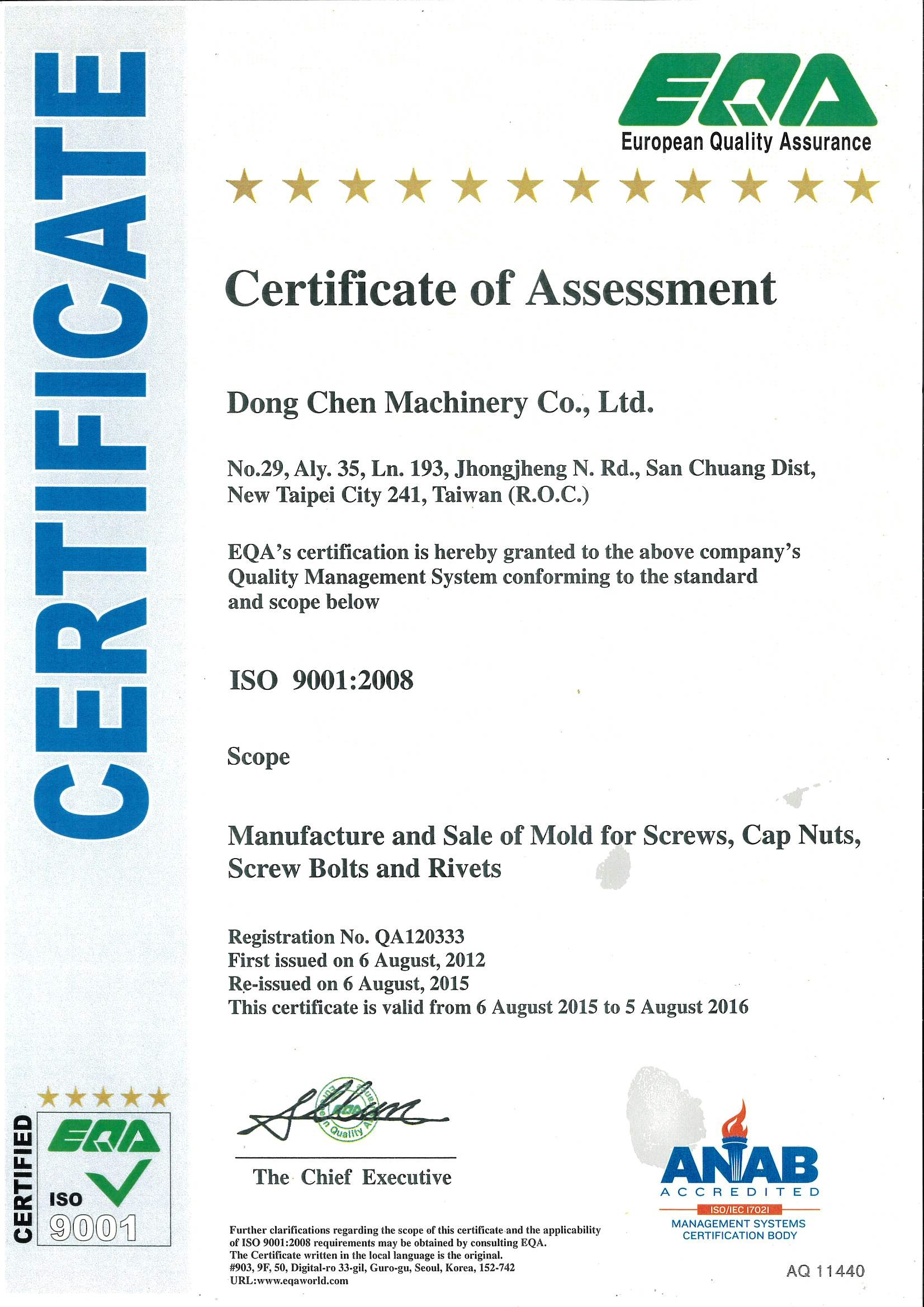

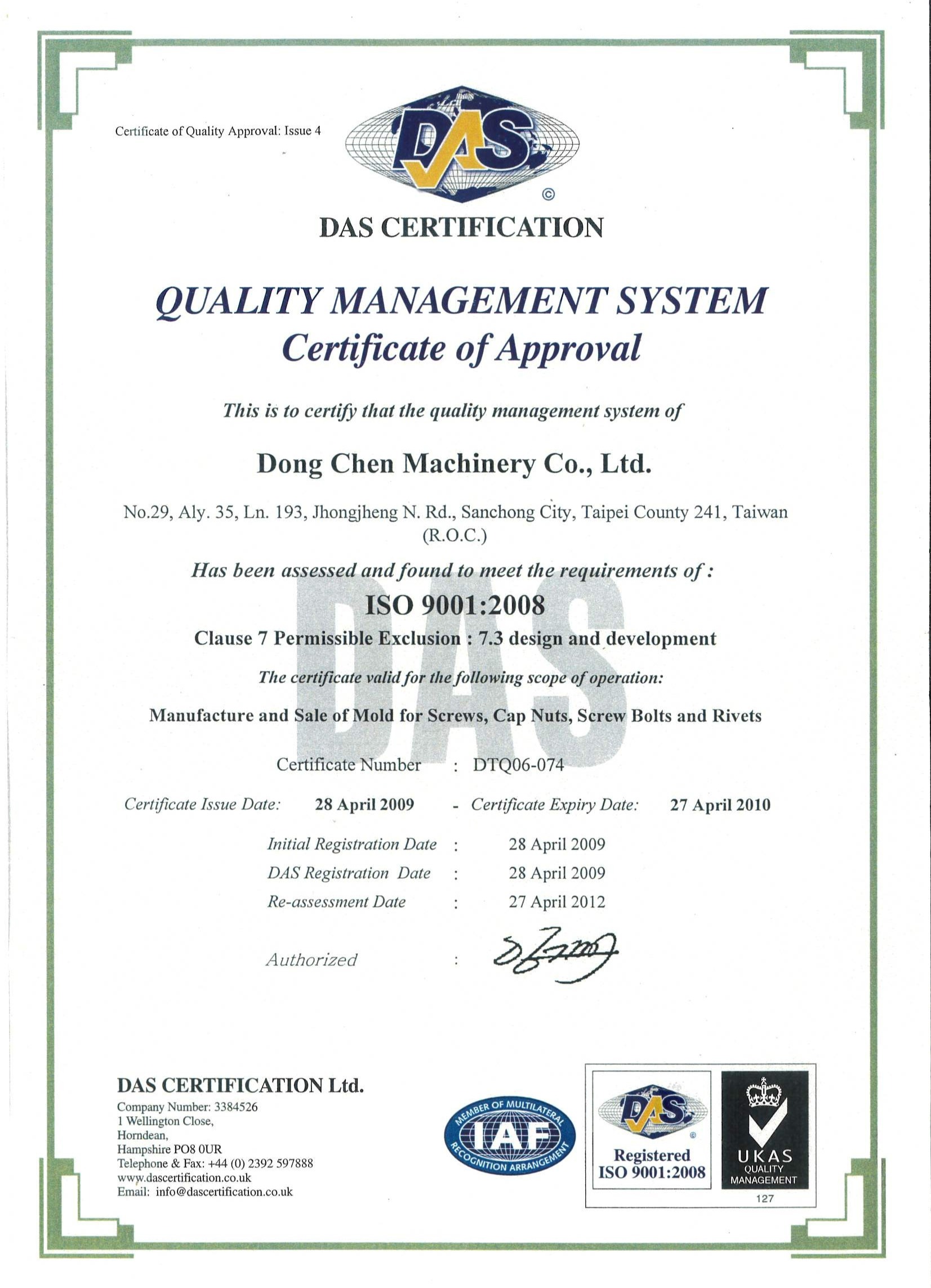

Since 1988, Tong Z has focused on screw and carbide molds. With over 30 years of experience, we’ve upgraded our production with automation and advanced technology to ensure better quality and consistency.

More than a mold supplier, we are a trusted partner dedicated to improving our customers’ production processes. Through accurate design and reliable quality, we help increase efficiency, reduce defect rates, and cut costs.

Tong Z makes custom screw and carbide molds that follow international standards like DIN, JIS, IFI, ASME, and ISO. They work with all kinds of screw heading machines, cold forging tools, and special fastener production.

Tong Z | From Design to Final Forming

CNC Turning Machine

TONG Z uses a CAD/CAM 2.5D digital machining system. From drawing to machining, all steps are handled in-house to ensure stable processes and consistent quality. We apply this to EDM electrodes, mold case , thread die case , punch case, and toolings.

CNC Milling Machine

TONG Z uses a CAD/CAM 4.5-Axis simulation system for full digital integration from 3D design to machining. Targeting first and second punch shaps, serration, taptite screw, automobile screw, barrel nut and screw, and EDM engraving electrodes.

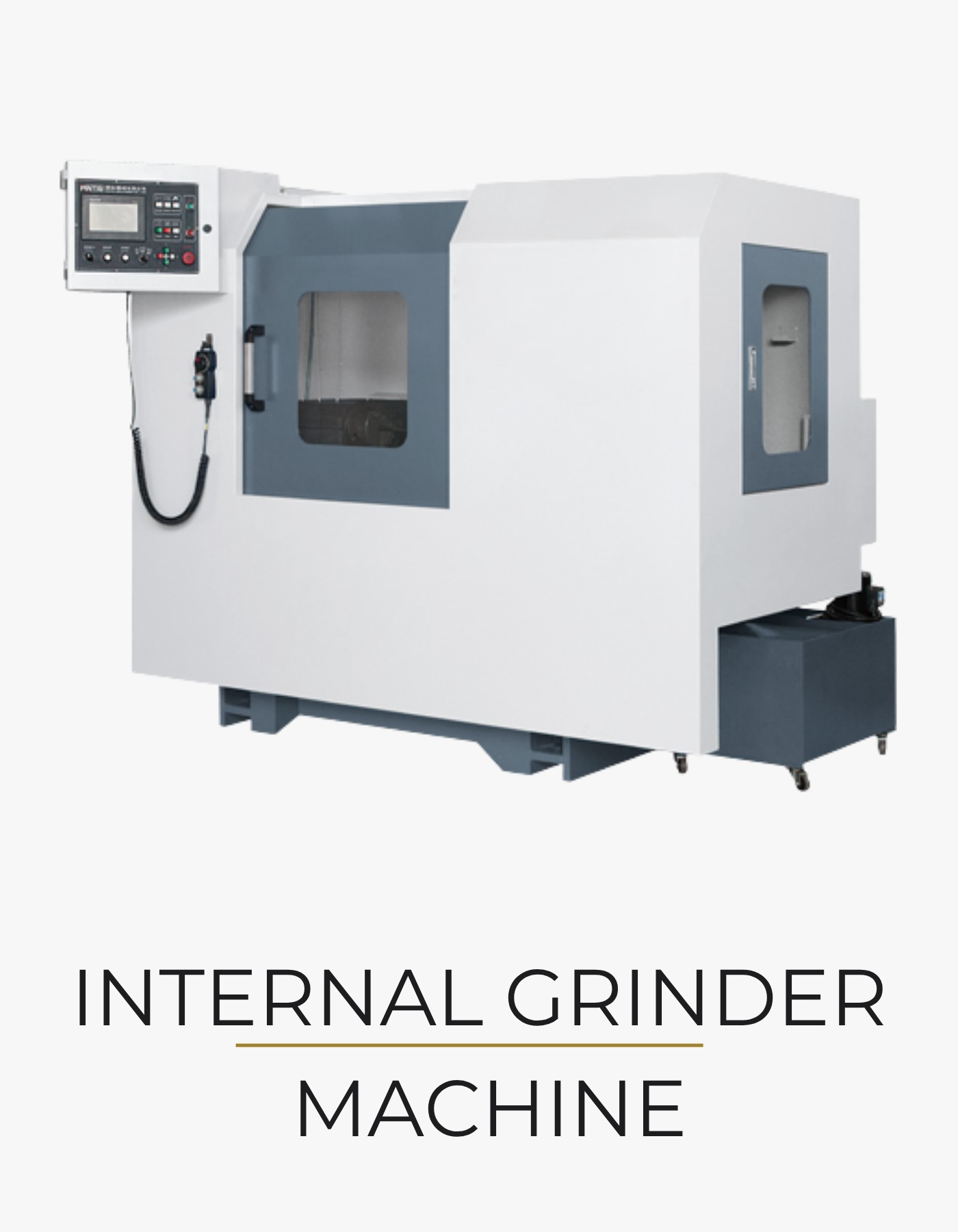

Grinding

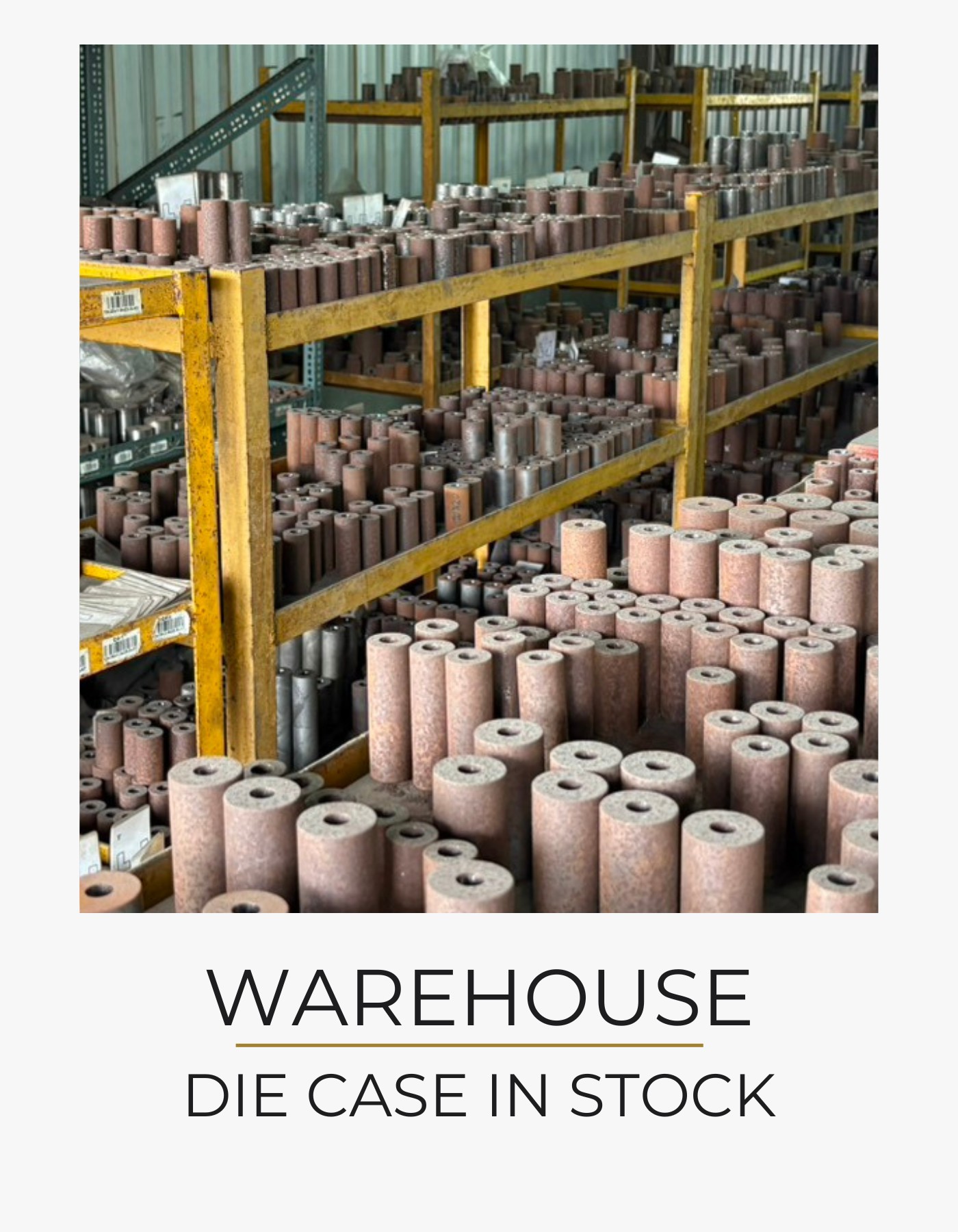

TONG Z uses a human-machine grinding system for internal and external grinding.Computer controls size, experts monitor to ensure accuracy and quality. Ideal for parts needing high roundness and concentricity, like Carbide insert , punch case , die case.

EDM / Self-Made Copper Electrodes

TONG Z has 30+ years of EDM experience and makes its own CNC-milled copper electrodes. We handle precise curves, small radii, and complex shapes with stable machining, solving process and size issues effectively.

Wire Cutting × Taptite screw mold

TONG Z was an industry pioneer using CAD/CAM and wire EDM for taptite thread molds.We have 20+ years of key expertise in this field. Focused on Hex punche, Six segment, taptite screw, TORX, 912, and custom fixtures.

Polishing × Quality

With 30+ years of mold-making experience, TONG Z uses fluid polishing, sandblasting, and expert hand-finishing to boost inner brightness, reduce defects, and extend mold life.